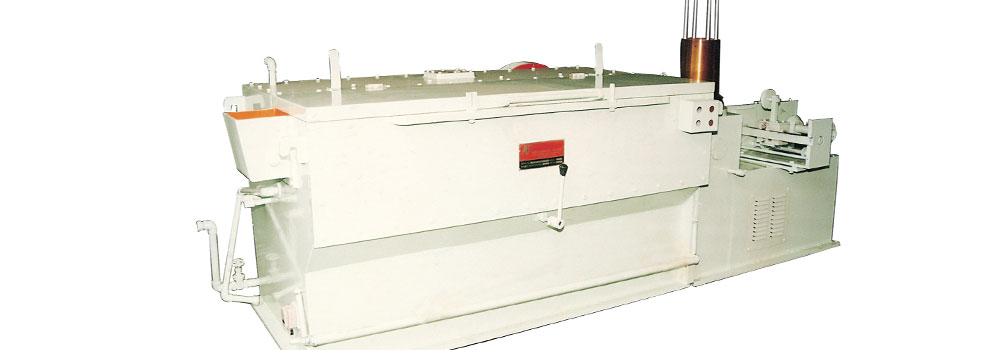

The wet draw machine is a slip type, straight line wire drawing machine which has become the standard of the industry for the production of carbon and alloy steel wires along with non ferrous wires. The wire enters the machine through the inlet by guide pulleys, through the first die and will exit the drawing compartment through the final die.

Dies can be fully submerged. The die-holders are machined from solid steel. Optionally the machine is equipped to spray wet-lube directly into the die and onto the drawing capstans By doing this we do not have to wait for the tank to fill before we can start the line.

The exit die is fully adjustable in all directions for easy setting of cast and helix.

The machine can be connected to a central lubrication system. The fill and drain of the drawing compartment is quick and ergonomic ensuring a simple and mud-free die replacement. The machine can be supplied with pre drawing blocks for better accumulations

Zenith production range includes wire drawing machines with 2, 4 or 6 independent cone arrangements with a range of 7 to 24 dies, for a finished wire diameter down to minimum 0,12mm

• Brass coated wires (steel cord, hose wire ).

• Electrolytic or hot dip galvanized wires.

• Stainless steel wire.

• High quality spring wire.

• Welding wire

• Copper wires

• Aluminium wires

• Solder wires

• Straight wire path, without transfer sheaves.

• Wire drawing only in one direction.

• High ratio between ring and wire diameter.

• Robust, anti-vibration steel frame.

• Heavy duty bearings and cone shafts.

• Cone shafts specially sealed to prevent bearings damages.

• Compact design

• AC main motor and slip-proof belt transmissions.

• Complete accessibility to all components for easy maintenance.

• Pre-wired, and programmed electrical cabinet

• Available with both horizontal and vertical capstans

| Type | NF Inter Machine |

F Inter Machine |

SS Inter Machine |

NF Medium Fine Machine |

F Medium Fine Machine |

SS Medium Fine Machine |

NF Fine Machine |

F Fine Machine |

SS Fine Machine |

||

| Model | WWD-7/9/11/13/15NF/I | WWD-11/13/15F/I | WWD-15/17/SS/I | WWD-19/21NF/MF | WWD-15/17F/MF | WWD-17/21SS/MF | WWD-21NF/F | WWD-21F/F | WWD-21SS/F | ||

| Material | Cu./AI. | M.S./H.C. | SS | Cu. | M.S/HC | SS | Cu. | M.S./H.C. | SS | ||

| Inlet Wires Dia (mm) | 3.2/4 | 2.5/2 | 2 | 2 | 1.6/1.2 | 1.2 | .7 | .7/.5 | .5 | ||

| Finishes Wire Dia (mm) | .4/.6 | .4/.4 | .4 | .2 | .15 | .25 | .122 | .1 | .122 | ||

| No. of Dies | 7/9/11/13/15 | 11/13/15 | 15/17 | 19/21 | 15/17 | 17/21 | 21 | 21 | 21 | ||

| No. of Cone Blocks | 2/2/2/4/4 | 2/4/4 | 4/4 | 4/4 | 4/4 | 4/4 | 4 | 4 | 4 | ||

| Working reduction % | 20.6 | 14.5 | 12 | 20.6/18 | 14.5 | 13 | 17 | 13 | 13/10 | ||

| Basic reduction % |

19 | 13.5 | 12 | 19/17 | 13.5 | 12 | 16 | 12 | 12/9 | ||

| Finishing Speed (m/sec) | 10/12/15 | 8/10/12 /15 |

3-5/5 | 15/20 | 10/15 | 5-6 | 20-25 | 15-20 | 10 | ||

| Drive Trans | Gears | Gears | Gears | Gears | Gears | Timer Belt | Timer Belt | Timer Belt | Timer Belt | ||

| Main Drive (k.w.) | 22.5/30/ 40 |

30/40 | 18.5/ 22.5 |

18.5

/ 22.5 |

22.5/ 30 |

11 | 15 | 15 | 5.5 | ||

|

Control AC/DC/ Inverter |

As Per Specs |

As Per Specs | As Per Specs | As Per Specs | As Per Specs | As Per Specs | As Per Specs | As Per Specs | As Per Specs | ||

| Largest Step Dia | 250 | 250 | 300 | 200 | 225 | 200 | 150 | 150 | 150 | ||

| Extractor Capstan Dia | 250 | 250 | 300/250 | 200 | 200 | 200 | 150 | 150 | 150 | ||

| Cone Material | H.C.H.C./T.C. | T.C./ H.C.H.C. |

H.C.H.C. | H.C.H.C. / T.C./Ceramic | T.C. / H.C.H.C. | H.C.H.C. | H.C.H.C. / Ceramic | T.C. / H.C.H.C. | T.C. / H.C.H.C. | ||

| Spooler | Ind. Drive | Ind. Drive | Ind. Drive | Ind. Drive | Ind. Drive | Integral Drive | Integral Drive | Integral Drive | Integral Drive | ||

| Bobbin Size mm (din spec) | 400 | 250 | 250 | 200 | 250/200 | 200 | 160-200 | 160-200 | 160-200 | ||

| Abbreviation Used • NF - Non Ferrous • F - Ferrous • RBD - Rod Break Down • Inter - Intermediate • Ind. - Independent | |||||||||||