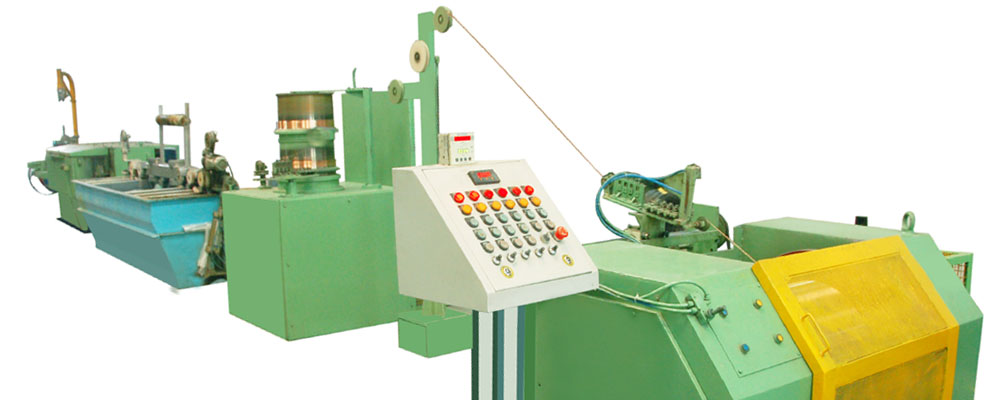

Zenith weldaids limited has consolidated its place among the most important companies in the design, production and assistance of drawing of all types of metal wire, with specialisation in CO2 welding wire. Wet drawing lines, wire pay-offs, take-ups and copper- plating tanks are all part of the exclusive series of advanced technology offered by zenith, with increasing quality and skill since 1989

• Payoff

• Spool Payoff

• Pneumatic pusher

• Dry drawing single block

• Wet wire drawing machine

• High speed copper coating tank

• Accumulation capstan(BB-TYPE)

• Take-Up (Spool Type)

It is used to unwind the carbon steel(WR3M) wire rod for the dry drawing.

This equipment permits to load the coils without stopping the dry drawing line.

The pay off consists of a welded frame and a pair of opposed hardened steel pintle mounted in substantial frame support. The inboard pintle will be fixed axially. A pneumatic disc brake is incorporated for holding the bobbin steady when stationary.

The outboard pintle is fitted with a “live” centre which can be moved axially by pneumatic means to open and close the pintle. When the spool is in position, the “live” pintle is locked in position so the spool is held even if the electricity or air pressure fails.

A pneumatic pusher is included to facilitate the loading of the empty reel.The payoff reel and wire line is totally guarded and fitted with mechanically interlocked safety switches.

• Capstan dia – 400 mm

• Wire inlet - 2.0 mm

• Power required- 10 hp

• Diebox-static(rotating dieboxes as option)

• Front guard-window type

As a pre drawing capstan with accumulation and overhead deviation transfer systems(OTO) The capstans and the drawing dies are water cooled.

The die holders are combined with lubricant boxes and are adjustable in order to exactly regulate the wire running direction.

The machine body is made up of heaviest mild steel construction. The capstan is made of a special cast and surface treated in the accumulation area to achieve a longer durability.

The wet draw machine is a slip type, wire drawing machine which has become the standard of the industry for the production of welding wires.

the wire enters the machine through the inlet by guide pulleys, through the first die and will exit the drawing compartment through the final die.

Dies can be fully submerged. The die-holders are machined from solid steel.

Final die is rotating type.

• Max. inlet wire diameter: 2.0mm

• Min. outlet wire diameter: 0.8mm

• Number of drafts: 11

• Max. speed: 12 m/s

• Submerged horizontal tungsten carbide coated /brazed cones wire drawing system

• Final rotating die system and rest fixed dies

• Toothed V-shaped belt transmission

• Standard motor power: 60hp

• Possibility to skip drafts

Zenith supplies high speed six chambered copper coating tanks made up of PP and FRP. In order to achieve high speed continuous production of copper coated MIG Welding wires.

Features

• Material to be treated: Welding wire, T.S. 100 kg/mm² max, Carbon content = 0,06÷0,15%

• Wires range: from 0,8 to 1,2 mm

• Wire speed: 12 m/sec. max

Process:

First chamber-water wash to eliminate left over lubricant and absolute cleaning of wire

Second chamber – Pickling type of bath H2SO4+H2O

Third chamber-Water wash to eliminate acid coming from second chamber

Fourth chamber-Coppering: 400 litres, type of bath CuSO4+H2SO4+H2O

Fifth chamber-Water wash

Sixth chamber-Lubricant for pinch/skin pass

• Capstan dia – 400 mm(BB-type)

• Applicable Wire -0.8mm-1.2 mm

• Power required-15 hp

• Front guard-window type

• Accumulation speed-12m/s

This is again a vertical block of BB-type for accumulation of coated wire before spooling.

This block is of great importance and relevance for maintaining the continuos nature of the welding wire production.

The machine body is made up of heaviest mild steel construction.

The capstan is made of a special cast and surface treated in the accumulation area to achieve a longer durability.

The capstans are water cooled and the block unit comprises of killing roller unit along with with wire transfer arm.

• Spool type-horizontal

• Size-din630-din800(customer specified)

• Spooling speed -12m/s

• Front guard-window type

• Spool locking-pneumatic

• Spool loading/unloading-pneumatic

• Power required-10hp-15hp

The copper coated MIG welding wire is take-up on spools using spoolers.

This is the final operation in MIG wire processing lines.

Spoolers work in combination with wire drawing machines and are used to take up drawn wires on to rigid or collapsible machine spools according to DIN or customer standards. We offer a comprehensive series of spoolers, in several sizes for various spools an wire ranges. The spool is taken up between two pintles, one is pneumatically operated.

A pneumatic lifting-device with the functions "lift, lower and move spool sideward" is used for the loading and unloading of the spools. This allows a quick and trouble free exchange of spools. Wire laying is by means of a laying carriage, driven by a gear motor a mechanical traverse.