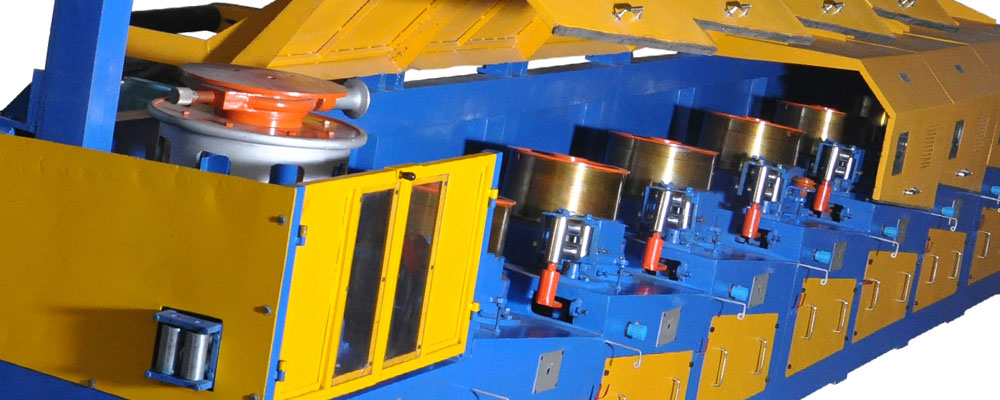

Straight line drawing machines can be delivered in various model sizes, systems and designs. Details as for example size and number of capstans, mechanical traction forces, speed, performance and drive type etc. are fixed upon customers` request or according to project planning.

Better productivity due to higher drawing speeds in normal production

High degree of reliability

superior wire quality due to a gentler handling of the wire during the drawing process (less wire deviations, no torsion etc.) as well as an optimised wire cooling

Better environmental conditions due to increased dust protection, air cooling required only for large diameter high carbon wires

Greater flexibility and lower current consumption due to modern drive technology.

The equipment consists of main reduction gear box.die casing box, drawing capstan and electrical control system. The drawing blocks are vertically fixed in fabricated mild steel body. The gears are lubricated with oil.

In order to lower residual heat on the surface of the block, the drawing capstans and die boxes are water cooled and air cooled

• sensor roll control

• narrow gap Capstan cooling system

• Pneumatic, high speed brake system

• Computer drawing system

• Frequency controlled A.C.-drive

• Diagnostic system

• Digital speed control system

• Stripper block

• Rotating die holder

• Soap boxes with stirrers

• Die take- up cassettes

• Dust suction systems

• Environmental guarding

• Wire diameter measuring heads